Air Compressors

Rotary Screw Air Compressors Tailored to Any Scale

Whether it’s a compact workshop or expansive manufacturing facilities, Air Center Inc. provides a selection of air compressors with diverse designs, featuring both standard specifications and custom options. Engage with our factory trained experts to delve into the effectiveness of Kaeser air compressors. These compressors are widely acknowledged for their exceptional efficiency in the market, epitomizing the reliability of being “Built for a Lifetime.”

Comprehensive Support for Air Compressor Systems and Design

When it comes to air compressor solutions, Air Center Inc. is your primary destination for expert advice, thorough system design, and seamless installation services. We extend our support to include air dryers and accessories, refurbished air compressor systems, and the supply of all essential parts and services you might require. Connect with us today at 610-837-6700 to converse with one of our team members and discuss how we can assist you!

Outstanding Choices in Compressor Selection

Explore a variety of exceptional compressor options, including:

- Kaeser Rotary-screw compressors

- Refrigerated and Desiccant air dryers

- Oil-free Compressors

- Blowers

- A comprehensive selection of Kaeser air treatment products

- Process chillers

- Portable compressors

- Rental compressors and dryers

Rotary Screw Air Compressors

Sigma Frequency Control

Specifications

Models: SFC 18 to 515

Horsepower:

25 to 450 hp

(18.5 to 515 kW)

Capacities: 22 to 3134 cfm

Standard pressures: 80 to 217 psig

Kaeser’s Sigma Frequency Control (SFC) compressors integrate our one-to-one direct drive compressors and groundbreaking Sigma Control system with state-of-the-art variable speed drive technology. Utilizing large, slow-speed airends featuring the optimized Sigma Profile, these airends are directly linked to a standard motor through a maintenance-free coupling, ensuring optimal transmission efficiency.

Rotary Screw Compressor with Direct Drive 25-700 hp

Specifications

Models: ASD to HSD series

Horsepower: 25-700 hp

Capacities: 72-3000 cfm

Standard pressures 80-217 psig

Enhanced Efficiency

Through Kaeser’s one-to-one drive, the airend establishes a direct connection to the motor via a maintenance-free coupling, eliminating transmission losses. This direct drive mechanism in Kaeser’s screw compressors ensures exceptional performance, resulting in heightened energy savings.

Kaeser opts for oversized airends, meticulously chosen to generate the necessary output in both flow and pressure. In contrast to compressors employing small, high-speed, gear-driven airends, the one-to-one drive yields substantial savings.

Triple Advantages

- Efficient power transmission without losses

- Reduced power consumption

- Lower maintenance costs and associated downtime expenditures

Rotary Screw Compressors with V-belt Drive to 30 hp

Specifications

Models: SX, SM, SK and AS series

Horsepower: 3 to 30 hp

Capacities: 4.5 to 124 cfm

Standard pressures: 50 to 205 psig

Flexible V-Belt Drive System

Kaeser’s screw compressors equipped with a V-belt drive are cost-effective, efficient, and dependable. The automatic tensioning device guarantees outstanding transmission efficiency throughout the unit’s lifespan, thereby lowering maintenance expenses. Compressors featuring a V-belt drive are particularly adaptable in scenarios where an elevation in working pressure is required.

When Class “Zero” Quality Air is Required

The New Dimension in Oil-free Compression

Crafted with a thoughtful component arrangement and meticulous attention to detail, Kaeser’s 2-stage oil-free compressors are purposefully designed with the user in focus. The acclaimed quality of Kaeser ensures peace of mind and reliability built to last a lifetime.

OIL FREE Rotary Screw Compressors

Specifications

Models: CSG to FSG series

Horsepower: 50-450 hp

Capacities: 184-1772 cfm

Standard pressures 80-217 psig

Maximized Efficiency

Through Kaeser’s one-to-one drive, the airend forms a direct link to the motor via a maintenance-free coupling, eradicating transmission losses. Kaeser’s direct drive screw compressors exhibit remarkable performance, contributing to enhanced energy savings.

Kaeser employs generously sized airends, carefully chosen to meet the necessary output requirements in both flow and pressure. In contrast to compressors utilizing small, high-speed, gear-driven airends, the one-to-one drive results in substantial savings.

Triple Savings

- Efficient power transmission without losses

- Reduced power consumption

- Decreased maintenance and associated downtime costs

The Sigma Profile for Energy Efficiency

Kaeser’s exclusive Sigma Profile proves to be up to 20% more efficient compared to conventional designs. Manufactured with stringent quality standards, these airends assure prolonged operational life and exceptional reliability.

Sigma Control

The control system for the compressor incorporates an industrial-grade PC, an Intel® microprocessor, and a real-time operating system. Five distinct control configurations are at your disposal to accurately align compressor performance with air demand.

Automatic belt tensioning

The automatic belt tensioning mechanism guarantees exceptional transmission efficiency, contributing to heightened reliability in the drive system.

Cooling air filter mats

The ambient air utilized for cooling typically contains dust and particulate matter. Filter mats, through which cooling air is pulled into the cabinet, prevent early blockage of the cooler and inlet filter.

Efficient separation system

The majority of the cooling fluid is isolated from the air through centrifugal action within the separator tank. Any residual fluid undergoes separation through a 2-stage separator cartridge. This triple-action process effectively doubles the cartridge’s service life and diminishes fluid carryover to 2 ppm or less.

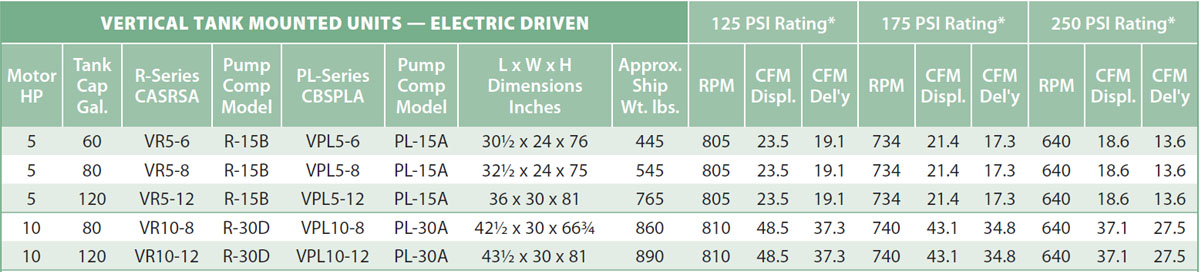

Champion 5-10 hp Horizontal Mounted Compressors

At Champion, our sole focus is on air compressor systems. We possess in-depth knowledge and comprehension of how our products apply in diverse operating settings. Our objective is to supply you with compressors that not only meet but surpass your expectations and needs.

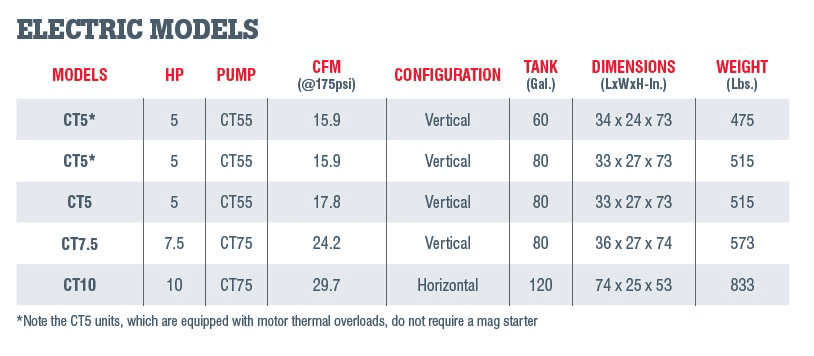

Curtis Electric and Gas Compressors

Quality and durability should not be compromised when purchasing an air compressor. That’s why FS-Curtis developed the CT Series. These reciprocating compressors integrate our renowned performance and reliability with a straightforward industrial design, establishing them as the most robust and cost-effective compressors in their class. The field-proven CT Series demonstrates a longer lifespan under similar conditions compared to other compressors claiming 100% cast-iron construction while still incorporating aluminum in crucial components. Ideal for light automotive, light industrial, and various other applications, they represent the optimal choice.

Champion 5-10 hp Horizontal Mounted Compressors

Champion specializes exclusively in air compressor systems, and we possess comprehensive knowledge and understanding of how our products perform in various operational settings. Our objective is to deliver compressors that not only meet but surpass your expectations and requirements.

Simplex Compressors

Key Features

• Magnetic motor starter

• 2-stage cast-iron pump adhering to ISO 9001 standards

(Except for 230/1 CT5 units equipped with motor thermal overloads)

• Slow-speed pump with V-belt drive

• Sturdy NEMA motor with UL-approved electric design

• ASME air tank

• OSHA-approved totally enclosed metal belt guard

• UL-approved pressure switch

• Automatic start-stop control

• Metal intake filter/silencer

• Manual tank condensate drain valve

• Dial read-out pressure gauge

• Loadless starting

• ASME-approved safety valve

• ASME-approved discharge valve

• Factory oil-filled

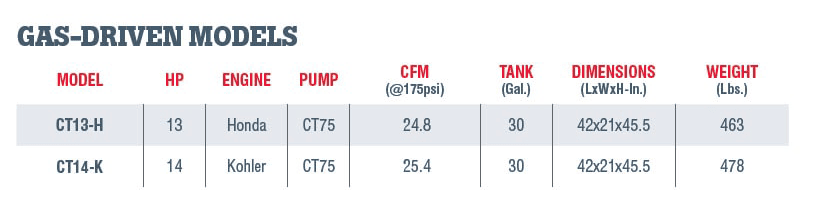

Gas-Driven Compressors

Key Features

• Robust 100% cast-iron pump construction for reliable operation

• Slow-speed design for prolonged life

• OSHA-approved totally enclosed metal belt guard

• ASME-approved air receiver

• 12V DC starter with alternator

• Engine idle control

• ASME-approved discharge valve